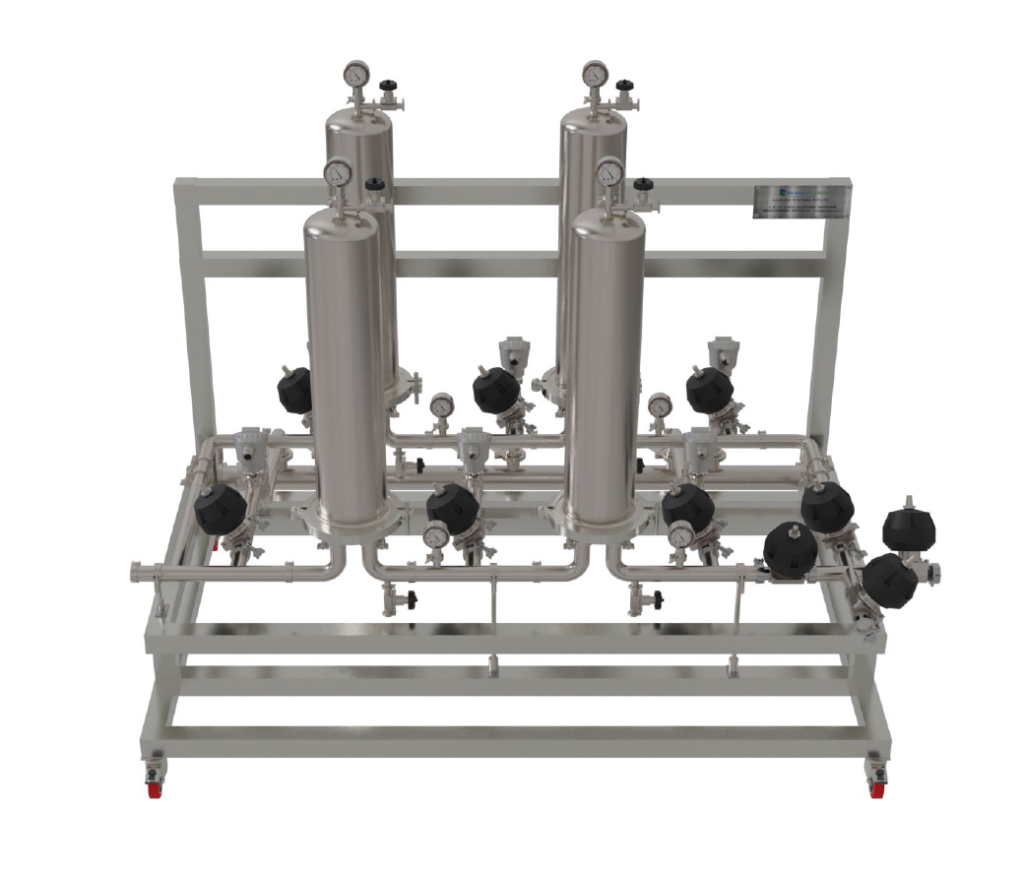

System Integrating BiopharmaceuticalSolution In One Platform

Filtration is one of the most important processes in

pharmaceutical & Biotech production. We design, build and

commission high-quality skid systems for every stage of

filtration. The filtration skids are custom designed for the

pharmaceutical & Biotech customers, and also for other

applications such as food, Breweries, distilleries production

facilities.

From regular harvesting skids to ultrafiltration (UF),

microfiltration (MF) and nanofiltration (NF) skids, we provide

engineering, assembly and construction of all hardware

components as well as the development of any necessary

software.

We can custom design and build filtration skids & systems,

fully tailored to the requested specifications, based on an

existing P&ID (Piping and Instrumentation Diagram), but

also from zero as per your desired specifications and

available space atyour facility.

Our design expertise ensures all factors in challenging

facility space constraints or cleaning specifications are well

catered and planned as required.

We work according to all of the latest relevant guidelines

and regulations, such as ASME, FDA & GMP. Upon

commissioning, we provide you with all of the required

documentation.

We can perform detailed 3D modelling of the

skidded system and sub-components and often uses this integrated

3D model as a training tool for customer maintenance personnel.

We can provide all required

piping, pipe support, and structural qualification calculations based on

our own internal standards, customer requirements, or internationally

recognized codes and standards.

We can design a lab scale trail or facilitate for

pilot scale trails for our syringe/ lab scale consumable modules as

required.

With advancements in membrane technologies, process automation in filtration are pivotal in meeting new age regulatory requirements. aFF Pro, Scale & Auto filtration skids are based on module and cartridge filtration technology

and have been designed to ensure the removal of specific micro-organisms or micro level impurity or charged

substances other contaminants by microfiltration.

Reduce your water consumption by up to 50% and your energy use by up to 30%, by combining our automated

custom engineered filtration skids and CIP system. Fill and heat the atmospheric tank with water during off-peak

hours to save energy costs, and use our heat-exchanger technology to recover heat from cleaning cycles. Recover and

reuse water from sterilization, decreasing consumption and waste. Our fully automated systems maximize efficiency

and control of the cleaning steps, enabling robust and repeatable processes, while lowering your environmental

footprint.

Available models

•Single filtration line

•Twin filtration lines

Applications: Clarification, filtration, micro-organisms retention before bottling or BIB (Bag In Box)

Segments: Wines, sparkling wines, flavored wines, beer, water and soft drinks

CIP System for Fully Automated Custom Engineered Filtration System

CIP system is piloted from PLC of fully automated filtration skid system – providing fully automated CIP services