System Integrating BiopharmaceuticalSolution In One Platform

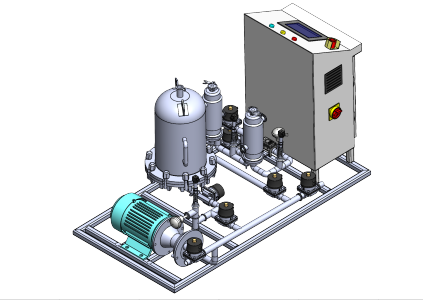

Bioneau® FilSTEMS™ Clarification Harvest System is a high-performance, skid-mounted unit designed for efficient removal of biomass, cell debris, and particulates from fermentation or cell culture media. Engineered for biopharma and API processes, it uses depth micron filtration for consistent, high-throughput clarification with product integrity. GMP-compliant and modular, it integrates seamlessly into upstream operations like mAbs production, enzyme clarification, and vaccine harvest, FMC Impurities, Color Improvement etc.

| Automation & Control | Fully automated PLC-HMI/SCADA-based system with 21 CFR Part 11 compliance |

|---|---|

| Compliance | 21 CFR Part 11 compliant |

| Filtration Stages | Multistage: Pre-filter, Bioburden Reduction, Final Sterile Filter; CIP/SIP enabled |

| Integrity Testing | Online Integrity Testing Port Provision |

| Material of Construction | SS316L (Electropolished, Ra < 0.4 µm); Optional: Hastelloy for aggressive fluids |

| Filtration Range | 0.2 µm to 10 µm (Cartridge or Capsule filters) |

| Flow Rate Range | 10 – 5000 LPH (custom-configurable) |

| Sanitary Design | Orbital welded SS316L piping with Tri-clamp connections & diaphragm valves |

| Documentation Package | IQ, OQ, DQ, FAT, SAT, P&ID, Calibration Certificates, URS |

| Data Logging & Audit Trail | Secure electronic records, password access, e-signature-ready; FLP Panel for electrical power |

| Installation & Service Support | Installation and immediate service support—both online and on-site |

Biopharma:

Vaccines

Active Pharmaceutical Ingredient (API)

Sterile Formulations