System Integrating BiopharmaceuticalSolution In One Platform

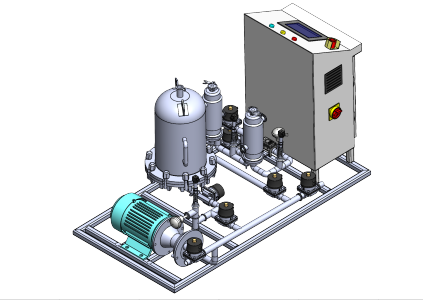

The Ultra-Filtration & Diafiltration (UF/DF) System is a cutting-edge membrane separation solution engineered for high-performance concentration and purification of biologics. Combining ultrafiltration for size-based molecular separation with diafiltration for efficient buffer exchange or impurity removal, this system delivers precise and scalable downstream processing.

It uses semi-permeable membranes with a molecular weight cut-off (MWCO) range of 1–100 kDa, enabling the selective retention of valuable biomolecules while efficiently removing solvents, salts, and low molecular weight impurities. Designed for flexibility, the system is available in both stainless steel and single-use configurations and comes integrated with automated controls to ensure consistent performance and full compliance with GMP standards and 21 CFR Part 11 regulations.

| System Type | Tangential Flow Filtration (TFF) with Cassettes or Hollow Fiber Modules |

| Filtration Purpose | Concentration (UF) and Buffer Exchange (DF) for proteins, enzymes, viral vectors |

| Membrane Cut-off | 1 kDa to 750 kDa (customized based on application) |

| Membrane Type | PES, PTFE |

| Surface Area Range | 0.1 m² to 50 m² or more (scalable from lab to production) |

| Flow Rate | 50 mL/min (lab scale) to 300 L/min (production scale) |

| Operating Pressure | 1 – 4 bar (15 – 60 psi) depending on membrane and process |

| TMP (Transmembrane Pressure) | 0.5 – 3 bar (adjustable and monitored) |

| Diafiltration Modes | Batch, Continuous (CSTR), or Fed-Batch |

| Recirculation Loop | Yes – loop with peristaltic/diaphragm pump for gentle fluid handling |

| Instrumentation | Pressure sensors (feed, retentate, permeate), flow meters, conductivity, pH, UV |

| Automation & Control | Manual / PLC-HMI / SCADA with 21 CFR Part 11 compliance |

| Cleaning | CIP & SIP compatible; automated or manual |

| Material of Construction | SS316L (electropolished), pharma-grade tubing, USP Class VI seals |

| Sterilization Options | Autoclavable modules; system compatible with SIP |

| Sample Ports | Sterile sampling ports on feed, retentate, and permeate lines |

| Compliance | cGMP, 21 CFR Part 11, ASME BPE, USP <88>, <87> |